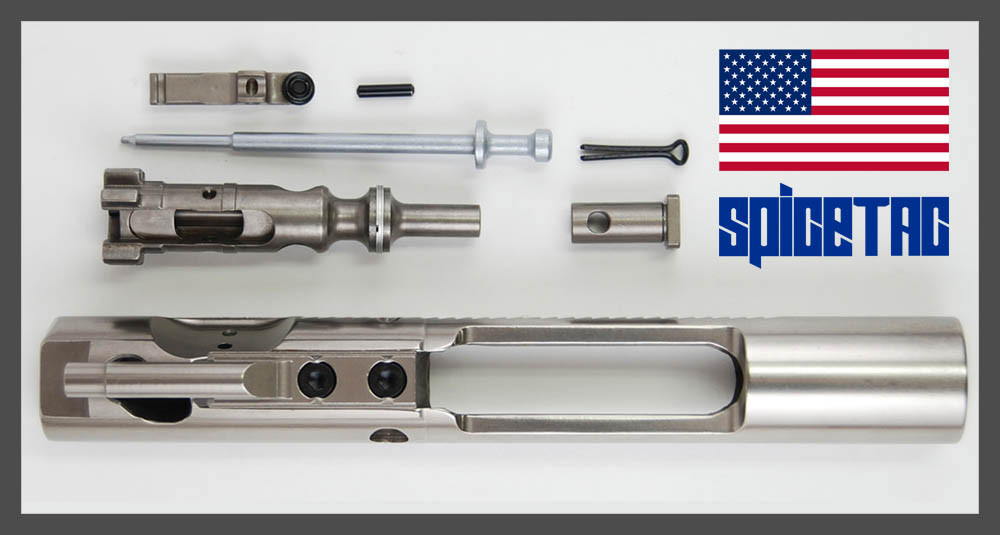

Toolcraft Nickel Boron BCG Review

Toolcraft makes bolt carrier groups (BCGs) in a variety of finishes and calibers but probably none have captured the imagination like their Nickel Boron (NiB) BCGs. Let's take a look at 'em!

Basics Remain the Same

A Toolcraft Nickel Boron BCG will start out as a solid chunk of specially blended 8620 Aircraft Quality steel. After machining and hardening and final machining all parts go out to be plated with Nickel Boron. Toolcraft uses UCT Coatings of Palm City FL for the Nickel Boron finish and that's a very good thing because they are considered to be the leader in that industry. UCT Coatings also does the Nickel Boron plating for the Fail Zero line of bolt carrier groups.

Durability

What does Nickel Boron bring to the table you might ask. For one - durability. As applied by UCT Coatings, Nickel Boron is so bullet proof that it is specified on Army 60mm and 81mm mortar tubes, Blackhawk helicopter hoists, and for hard use applications on some Navy ships!

Reduced Friction

Beyond durability, NiB has a surface slickness that has to be felt to be believed. When you handle an oiled Nickel Boron BCG you have to be careful that it doesn't slip right out of your hand. Seriously. Oil-on-glass-slick is what a friend of mine calls it, and Nickel Boron has it! That slickness makes for a BCG that operates much smoother than a regular BCG. All of the friction points in the operation of a BCG from reciprocating in the upper receiver to the cam pin and the gas rings riding inside the carrier benefit from this super slick surface.

Ease of Cleanup

Cleanup is easier in two ways. First, the finish is slicker so carbon is easier to get off. Second, the Nickel color makes any remaining dirt easy to spot and remove. When a NiB BCG is clean you know it's clean. The area of the bolt tail will still foul with carbon and I haven't seen a finish yet that makes this area any easier to clean, including NiB. If carbon build up in that area bugs you, it can be scraped off - a brass cartridge case works well. There are even scrapers made specifically for that area. I personally don't worry about it as it causes no negative function issues at all.

Bling Factor

Beauty is in the eye of the beholder and this is a good example of that. Some folks really like the contrast that the Nickel finish gives against an otherwise all-black rifle. Some folks wouldn't be caught dead with it. I personally like the contrasting look and think it looks like a million bucks - which is a nice segue into....

Cost

The Toolcraft Nickel Boron BCG generally comes with a middle-of-the-road price tag. That puts it somewhere between the Black Nitride on the low end and the Ionbond DLC or Titanium Nitride on the high end. One great thing about Toolcraft is that the reasonable prices allow you to get a great finish like Nickel Boron often for less than you could get a basic finish on a competing brand's BCG. Throw in the Toolcraft Lifetime Warranty and there is a lot to like!

Bottom Line

At the end of the day a Toolcraft Nickel Boron BCG is a quality option to consider when looking for your next BCG. As an upgrade from basic Black Nitride or Phosphate it brings a lot to the table.

Check them out here: Toolcraft Nickel Boron BCG

For more on the benefits of Nickel Boron see: Top 3 Reasons You Might Want a Nickel Boron BCG

See our review of the Toolcraft Black Nitride BCG: Toolcraft BCG - Best Black Rifle Secret Ever?

For specific comparisons of black finishes (Phosphate vs Nitride vs DLC ) see here The Best Black BCG Finish - Phosphate vs Nitride vs DLC

Recent Posts

-

Shooting The Massad Ayoob Group MAG Qualifier

What is the MAG Qual? The Massad Ayoob Group (MAG) Qual is a 60-round handgun qualificatio …May 27, 2023 -

10 Best Places To Buy Ammo Online [2023]

If you like convenience, selection and low prices, you owe it to yourself to shop online …May 20, 2023 -

Top 5 AR15 Bolt Carrier Groups

The bolt carrier group is the heart of your AR15. Let's look at some of the best! There a …May 13, 2023

![10 Best Places To Buy Ammo Online [2023] 10 Best Places To Buy Ammo Online [2023]](https://cdn11.bigcommerce.com/s-3oo7xhnyq8/images/stencil/160w/uploaded_images/where-to-buy-bulk-cheap-ammo-online.jpg?t=1660419625)